Product Modules

Bill of Materials(BOM) Management

Take command of your product data with Nora IPLM’s BOM Management capabilities.

Precise BOM Management

Take command of your product data with Nora IPLM platform’s BOM Management capabilities.

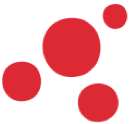

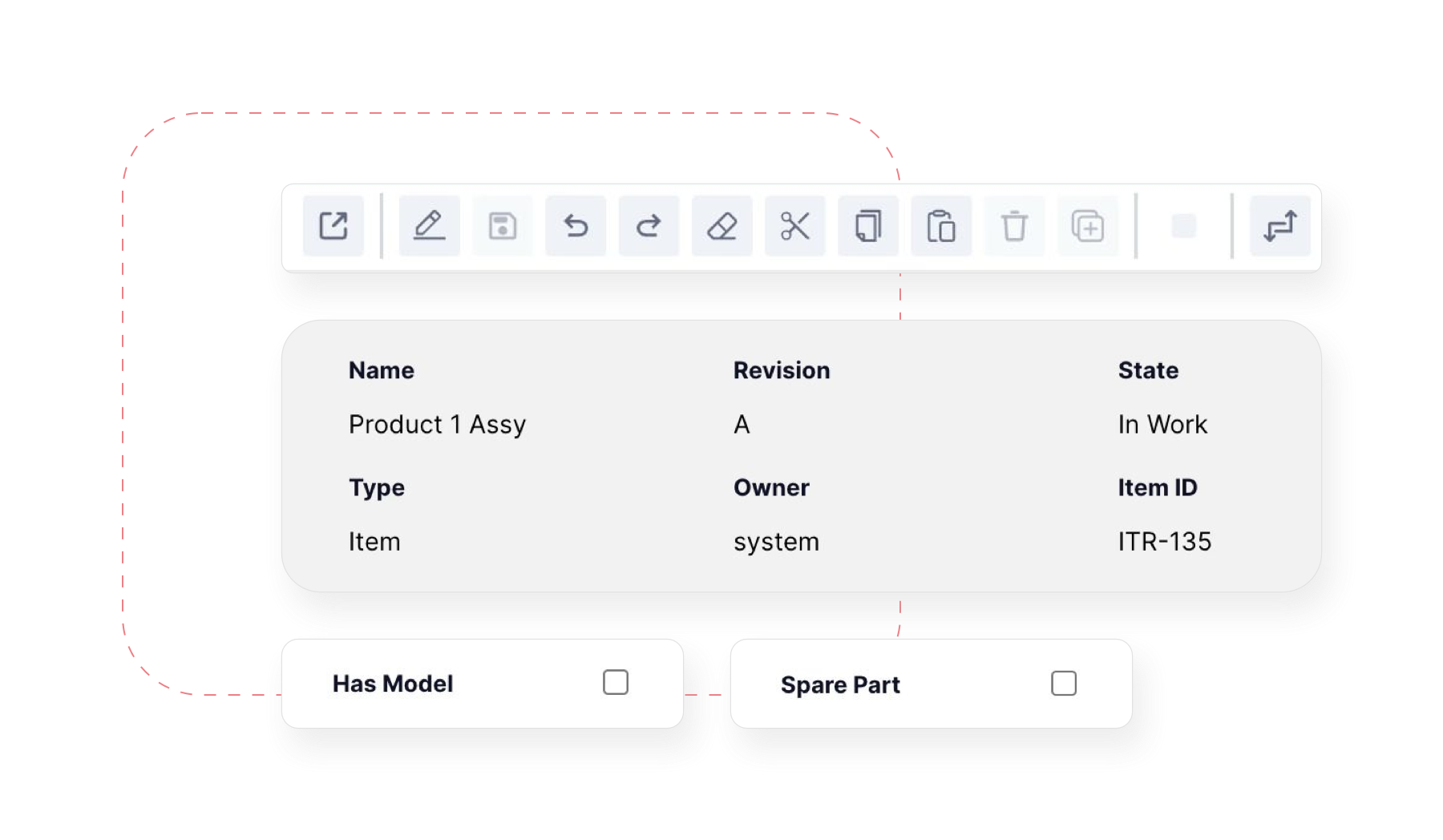

Our IPLM platform empowers you to create, update, and manage complex BOMs with unparalleled precision. Keep your components organized and your revisions up-to-date, minimizing errors and accelerating development cycles.

Real-Time Integration and Control

Transform your engineering process with our platform’s robust BOM Management capabilities and drive your projects forward with confidence.

With real-time data synchronization and integration with your CAD tools, you have the accurate information you need, right when you need it.

Optimize Your BOM Management

Effortlessly Manage Your BOMs

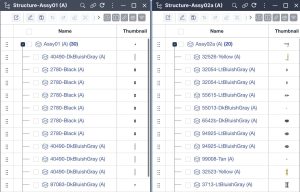

Analyze and Compare Multiple BOMs

Gain insights and make informed decisions by evaluating multiple BOMs with ease.

Create and Leverage BOM Baselines

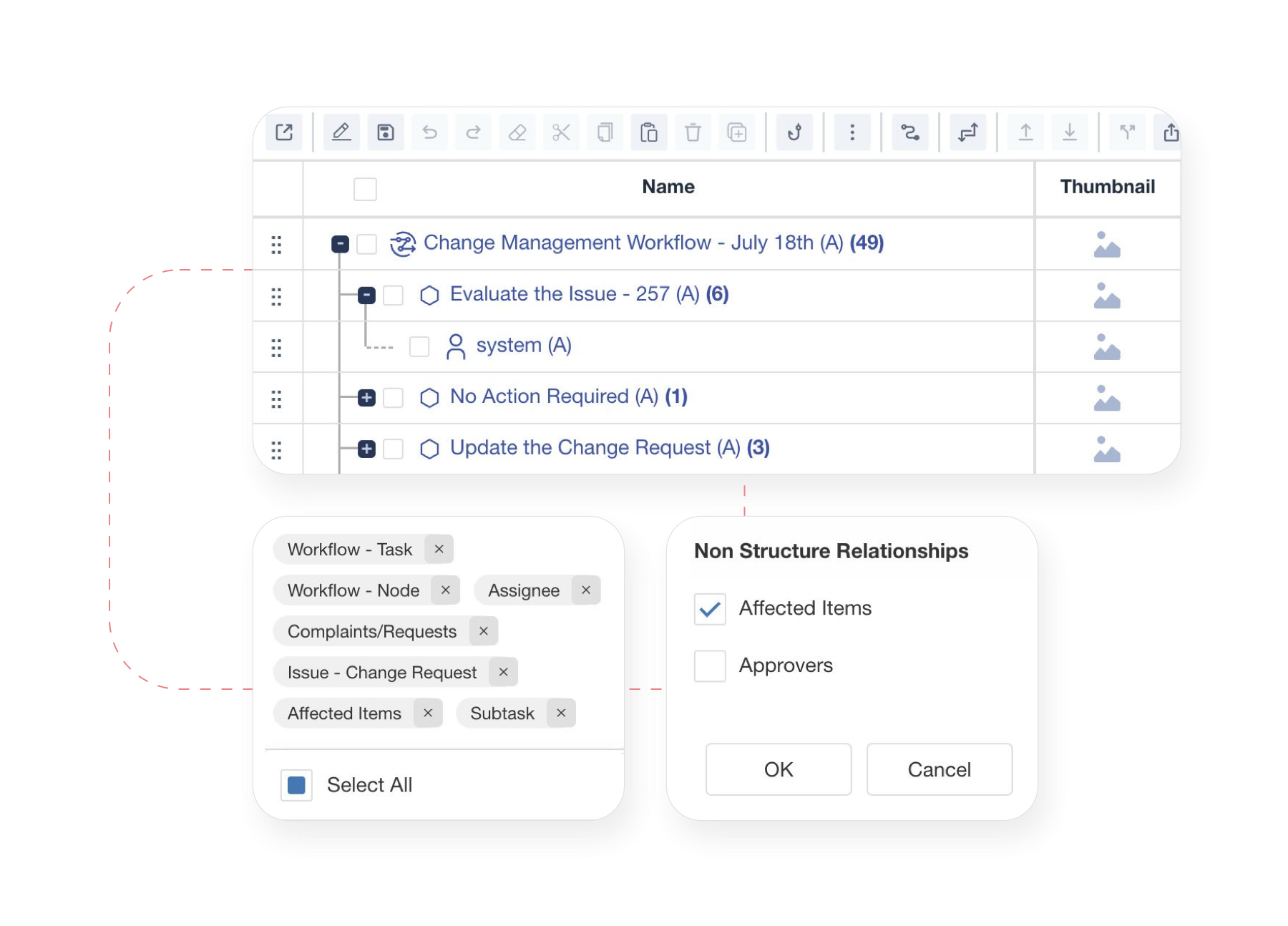

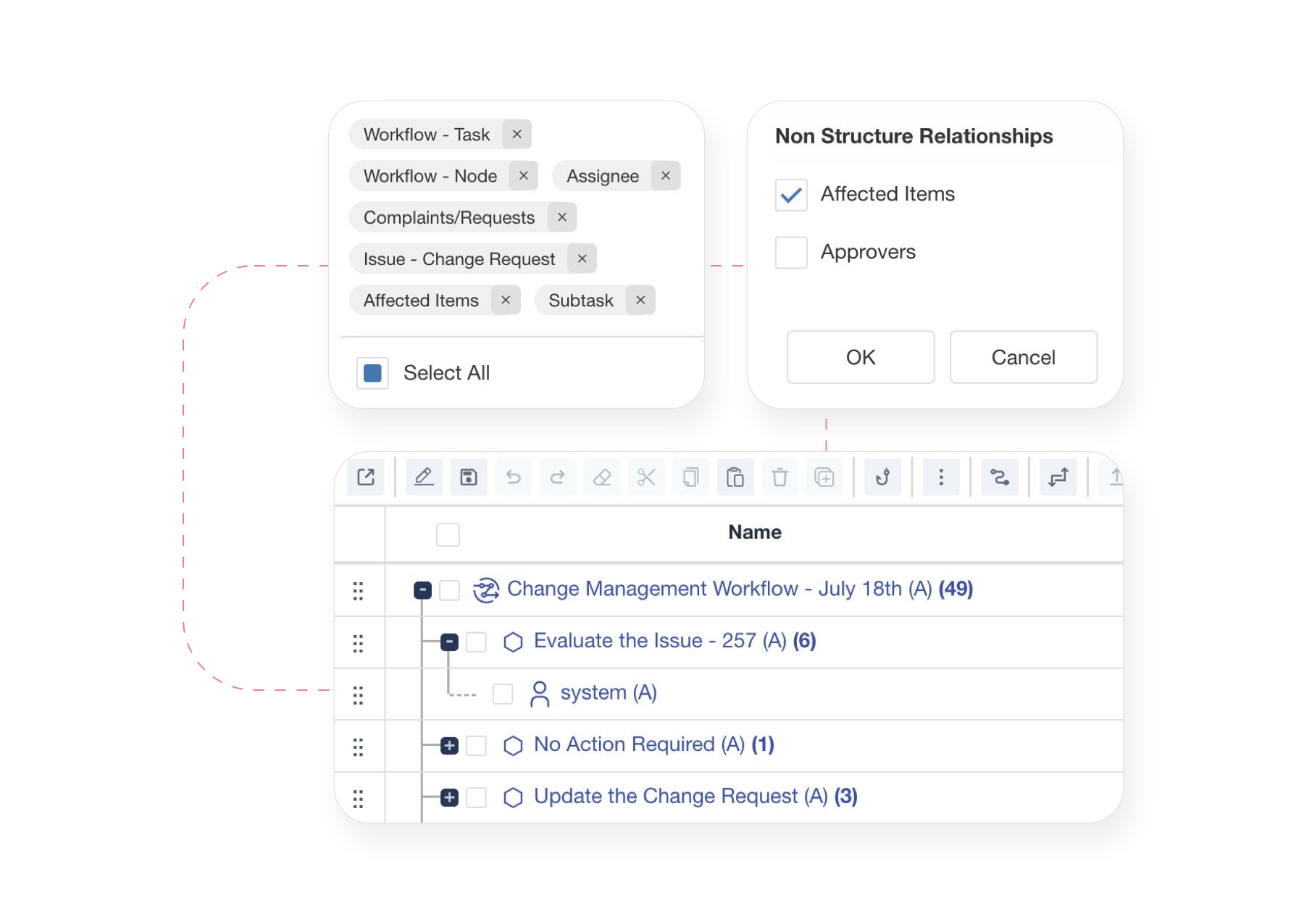

Streamline and Control Multiple Relationships for Impact Analysis

Dynamic Aggregation with Rollup Attributes

Automatically sum key attributes such as cost and weight across your BOMs with Rollup Attributes to have a comprehensive view of your product’s metrics at each assembly level.

BOM Management Features and Capabilities

Our Bill of Material Management features and capabilities include BOM structure editing, relationship management, alternative BOMs, reporting, cloning, historical tracking, 3D visualization, baselines, and much more. With these features, our platform helps you enhance efficiency, control, and accuracy in managing complex product assemblies and variations.

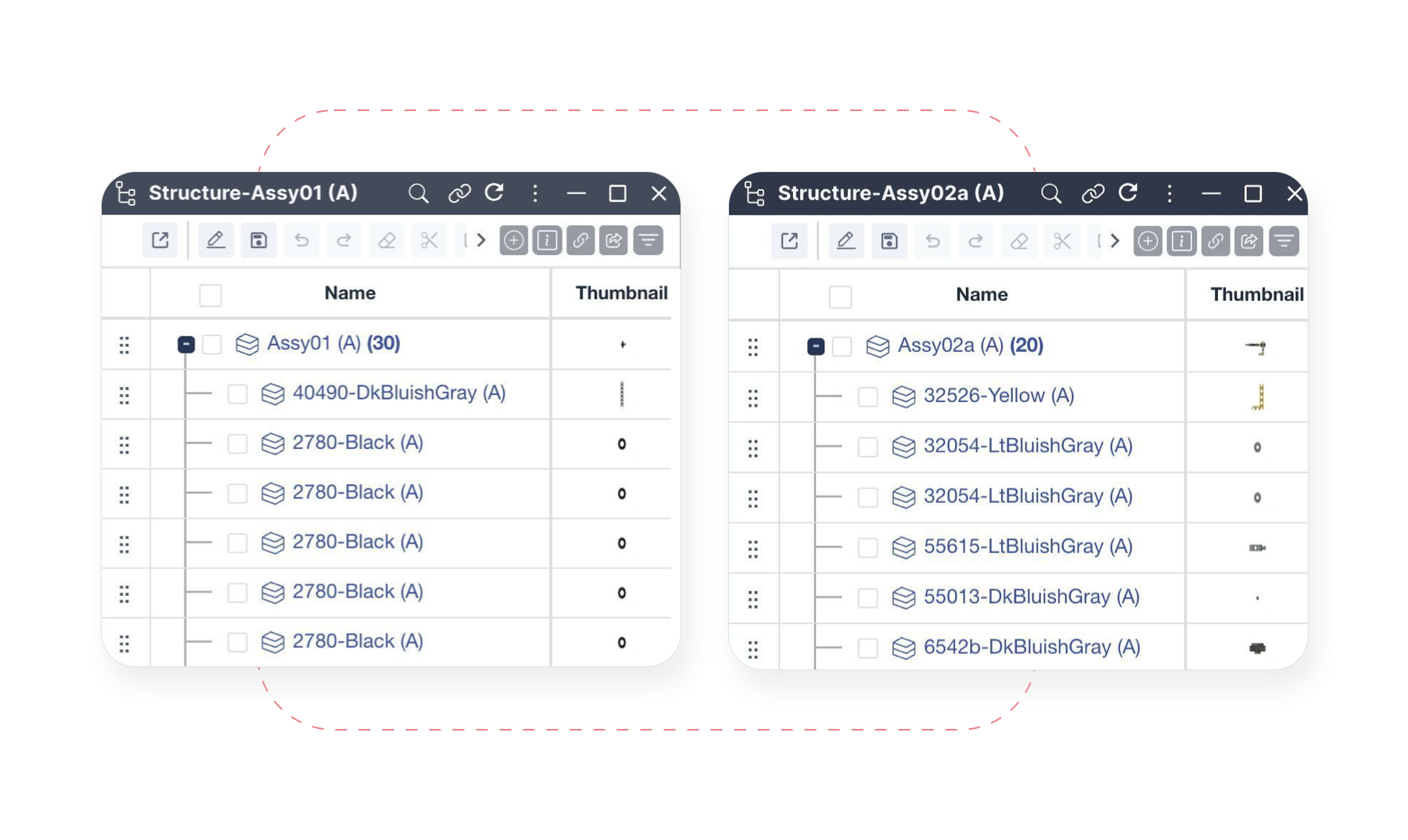

Define and manage relationships and hierarchies between parts in the BOM.

Manage and switch between different BOMs for the same product or assembly, accommodating variations and design changes while maintaining a structured approach to BOM management.

Assess the accuracy and completeness of BOMs to ensure data integrity and quality.

Generate and analyze reports based on BOM data for insights, trends, and metrics to support decision-making.

Clone existing BOMs for reuse in new projects or product variations, improving efficiency.

Manage historical data including connections and disconnections for tracking changes over time.

Import BOM data from external sources and export BOMs for use in other systems or formats.

Effortlessly edit BOM structures using Copy, Cut, Paste, and Drag-and-Drop features.

Easily compare multiple BOMs to identify differences and similarities for better management and control.

Create root items, add and manage subitems, handle revisions, establish relationships, and manage multi-level structures within the BOM.

Customize BOM views based on context or user needs for more relevant information.

Maintain multiple baselines for BOMs to track different versions or stages of development.

Quickly disconnect or delete irrelevant or outdated objects from the BOM.

Visualize BOM structures in an interactive 3D viewer to explore and analyze components with greater clarity and detail.

Navigate through different levels of the BOM to view detailed information and relationships.

Easily create new relationships between existing and new objects within the BOM.

Manage complex part numbers and names for precise identification and tracking.

View and manage BOMs in a flat, non-hierarchical structure for simpler analysis.

Manage BOMs specific to different functions or stages of the product lifecycle.

Receive alerts and notifications related to BOM changes, updates, or issues.

Connect with other applications and systems to enhance BOM management capabilities.

Perform bulk updates across multiple objects to streamline changes and maintain consistency.

Choose from various display options for viewing BOM data according to user preferences: Standard, Reverse, Flat, End Object(Leaf Nodes)

Classify BOM objects based on predefined categories for better organization and management.

Track the history of parts within BOMs to understand changes and revisions over time.

Categorize parts within the BOM based on type for better organization and management.

Manage phantom BOM levels for components temporarily used in assemblies.

Handle both precise and imprecise BOMs to accommodate varying levels of detail and accuracy.

Manage documents related to products and BOMs for comprehensive documentation and support.

Analyze BOMs to determine where components are used and manage quantities accordingly.

Calculate and roll up costs, weights, and carbon footprints from BOM data for environmental and financial analysis.

Experience the Future of PLM

Join now to experience the next generation of PLM. With cutting-edge features and an intuitive design, our platform empowers you to manage every stage of your product’s journey.