What Is Bill of Materials (BOM) Management?

Imagine stepping into a manufacturing plant where every component, material, and process is perfectly aligned to produce a product with precision and efficiency. This is the power of BOM—Bill of Materials—a fundamental concept in the manufacturing industry that structures the items and materials needed to fulfill a product’s purpose.

In this blog post, we will explore the importance of BOM in manufacturing, break down the different types of BOMs, and discuss the challenges organizations face in managing them. We’ll also dive into how Nora IPLM can help streamline BOM management, maintaining accuracy, synchronization, and efficiency across departments and systems.

Multiple BOMs in an Organization

Contrary to the common perception that BOMs are solely used for manufacturing, especially by business units utilizing MRP/ERP systems, BOMs play a broader role. They are involved in various business activities before and after the manufacturing phase. In reality, there is no single BOM in an organization; instead, multiple BOMs manage different materials and structures to serve the unit’s purpose.

Some of the widely used BOM types include:

- EBOM (Engineering BOM)

- MBOM (Manufacturing BOM)

- PBOM (Production BOM)

- SBOM (Service BOM)

Additionally, there are more specialized BOMs like Costing BOM and Purchasing BOM. Other related structures include BOP (Bill of Process) and BOR (Bill of Resources), which, while not typical BOMs, define the overall manufacturing process alongside MBOM.

From a data management perspective, a global or enterprise BOM is crucial. It gathers multi-disciplinary definitions under one structure to ensure better integrity of complex products.

Synchronizing BOMs

When multiple BOMs exist for the same product, synchronization is critical. BOMs with incorrect information, outdated revisions, or out-of-sync structures can lead to costly problems. Examples include:

- Supplying incorrect materials to production lines in JIT/JIS environments.

- Sending outdated design data to mold suppliers.

- Missing long-lead items due to incomplete information.

- Incorrect cost calculations resulting in financial losses.

Change Management and BOMs

Change Management is essential for maintaining multiple BOMs in sync. Without a unified Change Management platform, it is challenging to keep BOMs integrated and trustworthy. Key aspects include:

- Conducting impact analyses during change requests.

- Maintaining a chain of changes in downstream units.

- Ensuring controlled implementation.

Even with existing change management processes, managing them in a single environment is crucial to avoid issues. A single dashboard for tracking ongoing changes and implementations is vital for success.

Configurable BOMs (150% BOM)

As companies aim to deliver more configurable and customizable products, static (100%) BOMs are insufficient. A configurable BOM is flexible, including all product variants and configurable items. It also tracks material history, such as revisions or replacements.

Using static BOMs for 100 product configurations would require maintaining numerous separate items, leading to complex relations. In contrast, a configurable BOM uses a single superstructure with changing effectivities and rules per configuration.

Different Views of a BOM

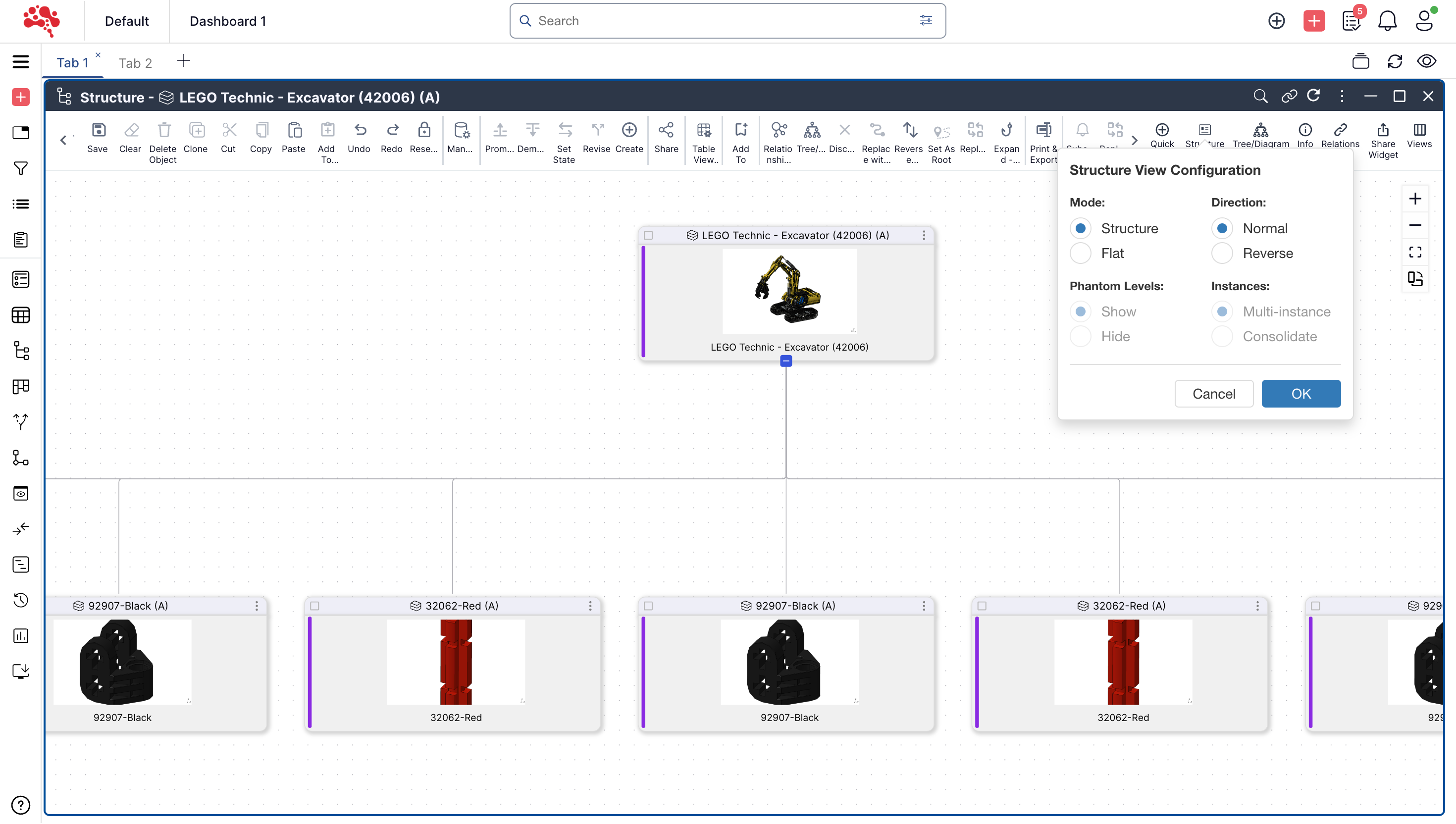

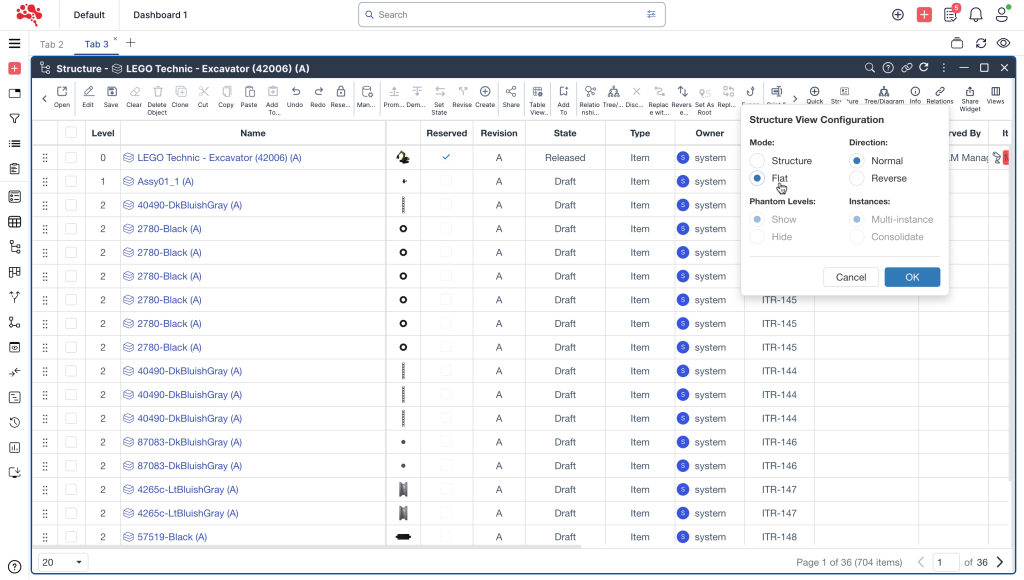

Different views of the same BOM are necessary to serve various roles and use cases:

- Flat View: Mostly used for planning and procurement.

- Where Used (Reverse) View: Shows the hierarchy in reverse, useful for analyzing material usage across products.

- Consolidated vs Multi-instance: Procurement may view total material quantities, while design and engineering need separate instances.

- Phantoms: Some departments use phantom levels for grouping materials, while others prefer these levels to be consolidated.

- Diagram View:

Managing BOMs in Organizations

Unfortunately, many organizations still rely on Excel spreadsheets to manage BOMs. This approach is problematic as it leads to data silos, making it difficult to maintain synchronization and leverage data for analytics and integration.

BOMs consist of dynamic data that evolve with changes such as material revisions or replacements. This necessitates robust revision management, baselining, and comparison capabilities.

Organizations with design and engineering departments often mistakenly equate CAD application data with their BOM. However, CAD BOMs are specific to design needs and may include unnecessary items. Exporting this data directly for manufacturing or purchasing in ERP systems is not advisable.

Collaboration around BOMs is essential, especially for large, mobile, and multi-site organizations. This collaboration should extend to third-party suppliers involved in product development and manufacturing.

Integrating BOMs with ERPs

Although BOM-related work occurs before integrating with ERP systems, MBOM is typically the right BOM for integration due to its appropriate structure and information.

In modern organizations, PLMs manage BOMs and automate integration with ERPs after final approvals in the change process. Any subsequent BOM changes in the PLM system should be automatically reflected in the ERP to ensure integrity between the two environments.

Discover the Key Benefits of Nora IPLM for BOM Management

Nora IPLM simplifies BOM management with features designed to boost efficiency and accuracy:

- Advanced BOM Management: Easily track and update Bills of Materials.

- Dynamic Workflows: Automate tasks to save time and focus on innovation.

- Real-Time Analytics: Make informed decisions with instant product data insights.

Nora IPLM centralizes BOM management, improving collaboration across design, engineering, and manufacturing, while eliminating data silos and reducing errors.

Ready to optimize your BOM management? See how Nora IPLM can streamline your processes today.